HSE Fundamentals

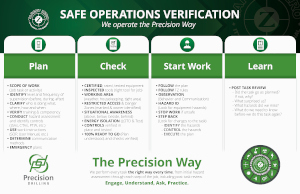

Safe Operations Verification

Precision employees assess hazards and ensure controls are in place to mitigate risk before the work starts. We execute to the plan, and if things change we stop and reassess. When the work is done we learn from our successes and our challenges. Every job, every task.

Risk and Hazard Assessment

Thorough risk assessment is key to identifying the proper controls to reduce risk. That’s why Precision utilizes our simple, yet comprehensive, Risk Assessment Matrix (RAM) to evaluate risks and threats to people, property, and the environment.

Observation and Hazard Identification

Precision proactively drives safe work behaviors and correction of unsafe acts and conditions through our structured Safety Observation Program.

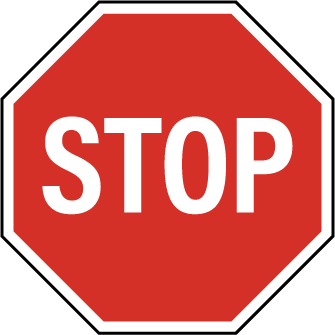

Stop Work and Step Back

All Precision employees are empowered and expected to stop work if the operation is not proceeding to plan, additional hazards are identified or not understood, or if something simply does not feel right. A structured Step Back discussion is then utilized to assess new and existing hazards before the work may proceed.

Observation and Hazard Identification

Proactive employee-to-employee engagements around safe work practices cultivate the learning, interdependent culture that leads to the highest levels of performance and safety.

Management of Change

Strong change management allows us to design safer equipment and processes by identifying and controlling potential risks in the design and review phase.

Critical Controls and Serious Injury and Fatality (SIF)

We focus on identifying the potential incidents that pose the greatest risk, enabling us to drive the control measures that prevent them.

Life Saving Actions

Fit for Duty – Be in a state to perform work safely

Working at Height – Protect yourself against a fall when working at height

Hot Work – Control flammables and ignition sources

Electrical – Protect yourself against electrical shocks

Bypassing Safety Controls – Obtain authorization before overriding or disabling safety controls

Safe Mechanical Lifting – Plan lifting operations and control the area

Work Authorization – Work with a valid permit when required

Driving – Follow safe driving rules

Confined Space – Obtain authorization before entering a confined space

Energy Isolation – Verify isolation and zero energy before work begins

Line of Fire – Keep yourself and others out of the line of fire

H2S Wells – Ensure that H2S gas concentrations are always at acceptable limits during work